Our Service

Fabricated to Fit Where Standard Won't

10+

Leading Brands

We’ve worked with

AI Innovation.

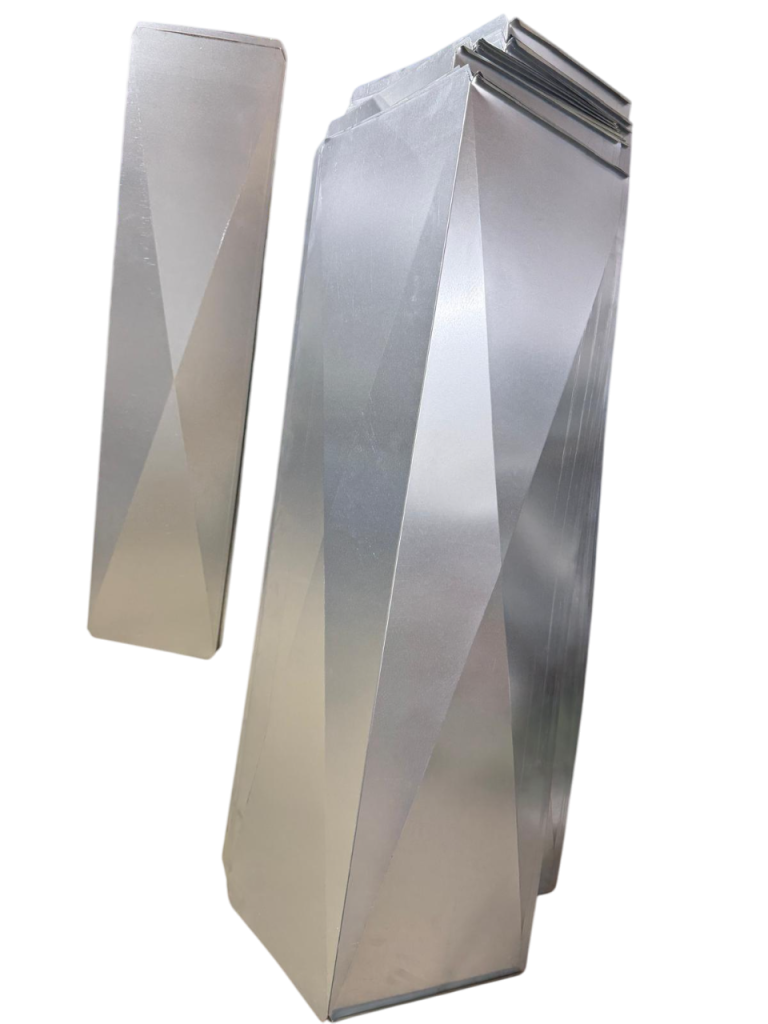

Not every project fits standard duct dimensions and fittings. Our fabrication shop produces custom ductwork solving unique challenges—from one-off specialty pieces to complete systems manufactured to your exact specifications..

When Custom Fabrication Makes Sense

- Unusual Dimensions

Tight spaces, odd angles, or non-standard sizes requiring ductwork made specifically for your application. - Material Requirements

Specifications calling for 16-gauge steel, stainless, or other materials not available in standard product lines. - Performance Demands

High-pressure systems, specialized applications, or code requirements needing engineered fabrication. - Aesthetic Considerations

Exposed ductwork installations where appearance matters as much as function

What We Fabricate?

- Galvanized Steel Ductwork – Standard and heavy-gauge construction

- 16-Gauge Welded Systems – Commercial kitchen and high-pressure applications

- Stainless Steel Ducts – Corrosion resistance for harsh environments

- Specialty Fittings – Custom transitions, elbows, and connectors

- Large-Diameter Sections – Industrial and commercial trunk lines

- Rectangular and Round – Any configuration your project requires

Fabrication Capabilities

- Precision Cutting – Computer-controlled equipment for accurate dimensions

- Welded Seams – Continuous welds for leak-proof, high-strength construction

- Custom Bending – Elbows and transitions made to exact angles and radii

- Flanged Connections – Bolted assemblies for large ductwork systems

- Reinforcement – Structural strengthening for long spans or high pressures

Industries We Serve

- Commercial Kitchens – Grease duct systems and exhaust ductwork

- Industrial Facilities – Process ventilation and heavy-duty applications

- Residential Custom Homes – Architectural ductwork for unique layouts

- Retail and Office – Exposed duct systems matching design aesthetics

- Manufacturing – Dust collection and specialized exhaust systems

Quality Standards

- Precise Dimensions – Pieces fit correctly the first time without field modifications

- Clean Welds – Professional appearance and structural integrity

- Proper Sealing – Leak-free construction meeting performance requirements

- Inspection Ready – Fabrication meeting all applicable codes and standards